Modular design that can build the best line composition at any time

NXT III

NXT III

One NXT III module covers an area of only 0.46 ㎡, achieving compactness.Limits.

Effectively improve the automatic management of OEE nozzle quality

Introducing the application software Auto Shape Generator, which solves

Problems associated with creating image processing data.

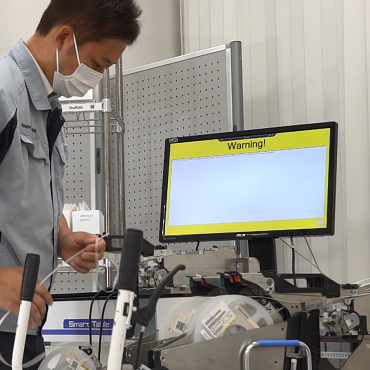

Control in advance and respond in time: introduce on-site improvement solutions

Case IPQC Expert

Introduce a field improvement solution IPQC Expert, from patch

Extract valid information from the machine’s production data, parse the change points, and

Provide the best solution for the problem that occurs.

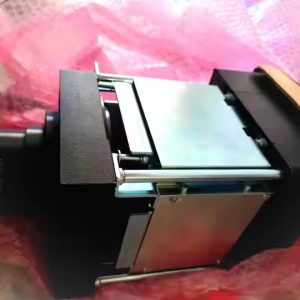

Fuji NXT pick and place machine

1.Prevent poor mounting caused by wrong material loading | Upper surface identification of components

Don’t (TVR) function introduction

The operator may use the wrong component type or place the wrong component when carrying the component.

Feed direction. For example, loading the tray onto the tray carrier is wrong

Orientation, or wrong component type when manually putting the component back into the tray…

2.Improve the mounting quality of flexible circuit boards | “TOP(Target

On Paste) mount “introduction

This paper introduces the use of self-adjustment function to suppress the occurrence of mounting flexible circuit board

Position offset mounting solution-TOP(Target On Paste)

Mount.

The quality in the mounting process is based on “QCD (high quality, low cost, fast delivery, high speed and high precision mounting with intelligent component detection sensor (IPS)